ENGINEERING

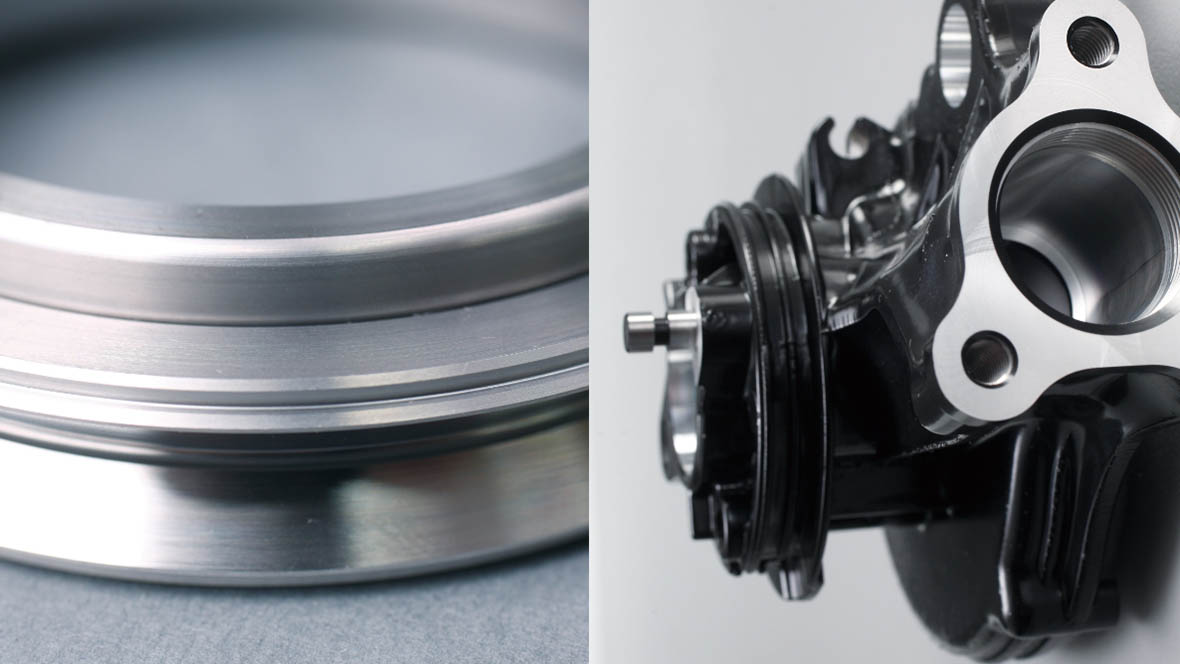

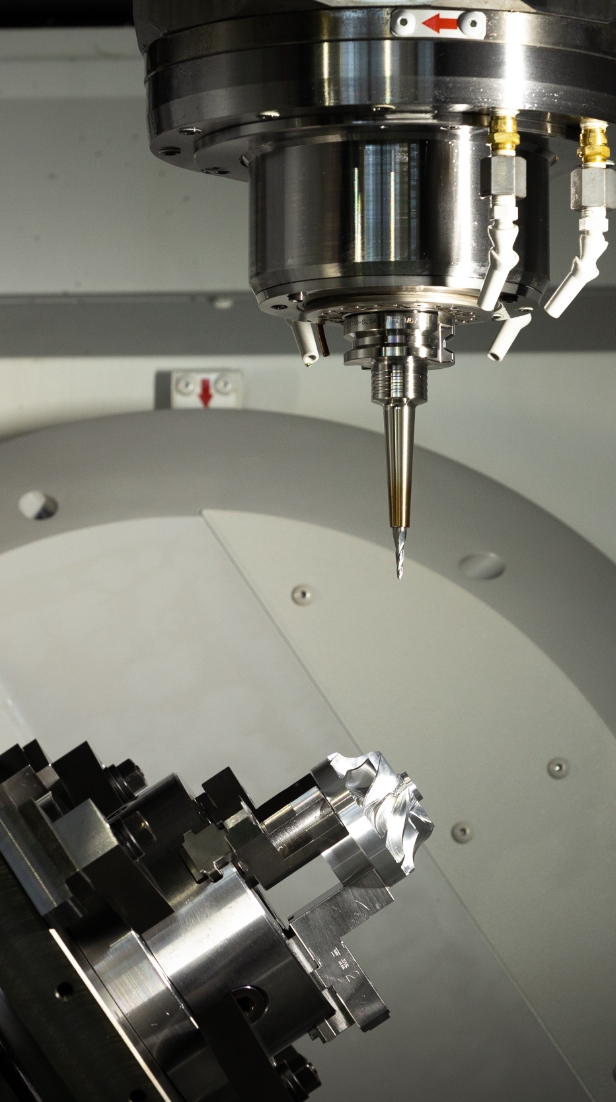

Our machining technology can realize the tolerance of 0.001mm.

As metal machining of today is getting more complex and diversified, customers demand higher quality, and higher efficiency.

SONEC meets customers’ expectation with the forefront technology of 5-axis machines and 3D CAD/CAM system,

and the difficult-to-machine metal machining which needs tacit knowledge.

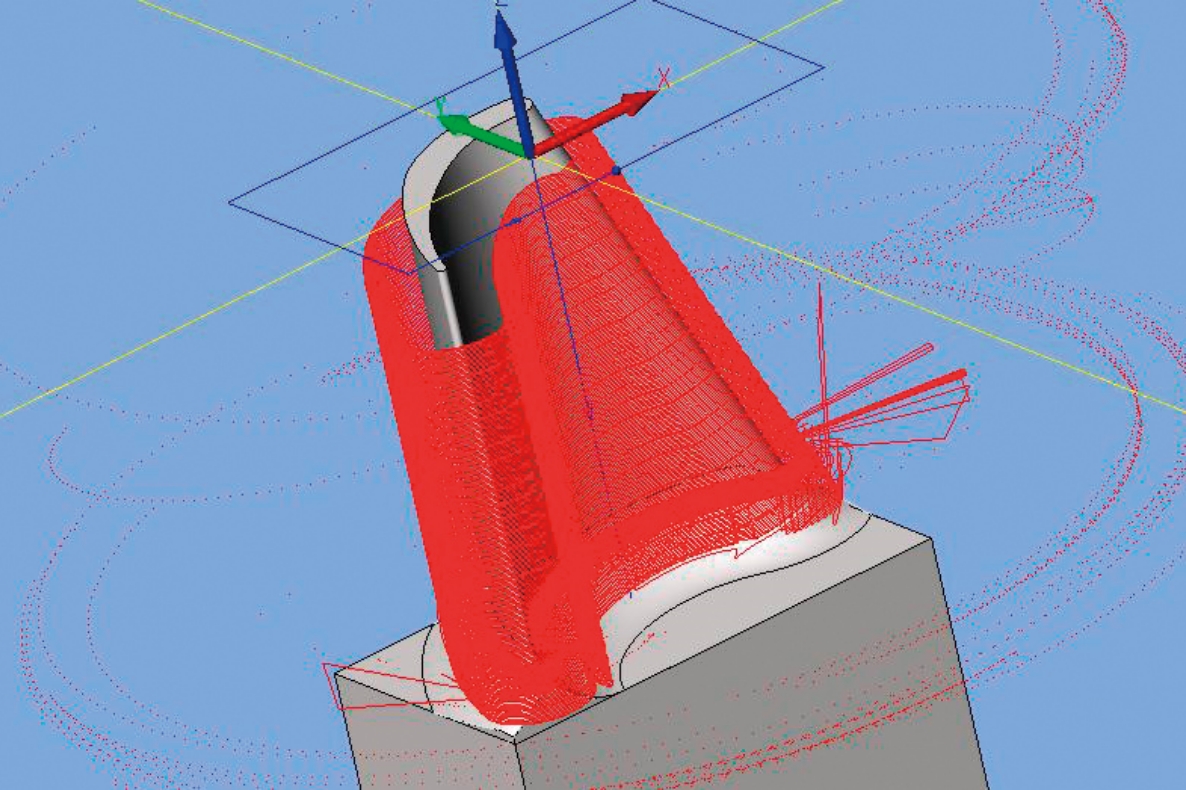

3D CAD/CAM

Our excellent 3D modelling technology can highly manage the modelling speed and its conformity.

One of our typical technologies is to create beautiful process path by the skilled programming with 3D CAM.

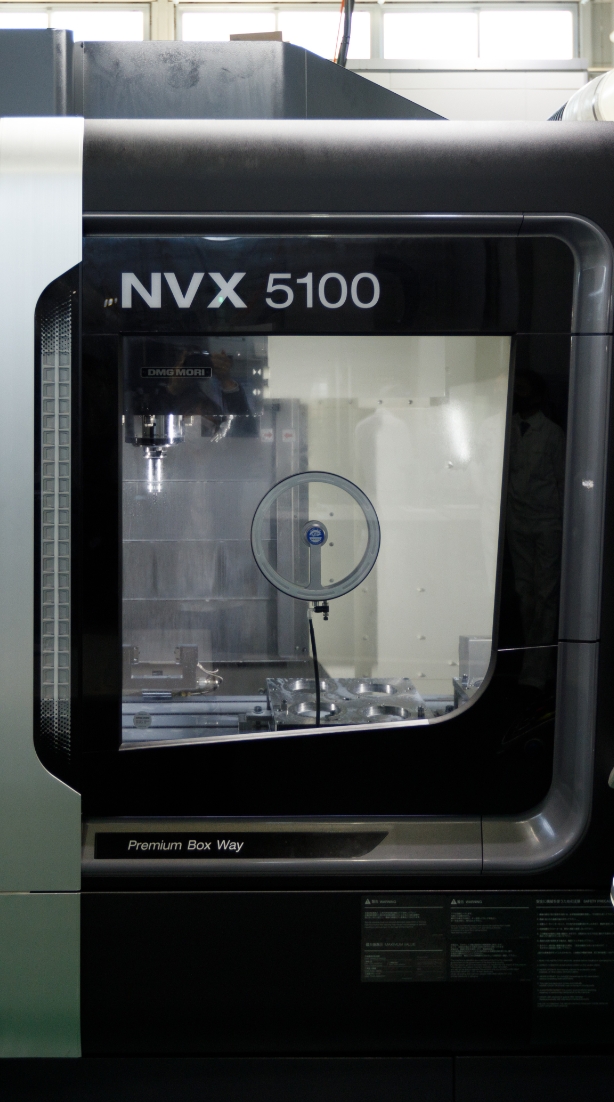

5-axis machining

We maximize the capability of high-class machines to realize the machining with the tolerance of 0.001mm. Our craftsmen can make the machines to machine parts quickly and more beautiful.

Machining

Each craftsman manages the operations of both lathe and machining center.

We can machine any kinds of work metals (SUS, Ti, alloy steel, Cu, Al alloy, etc.).

We can machine any kinds of mold materials (forged, casted, die-casted, MIM, lost-wax casted, etc.).

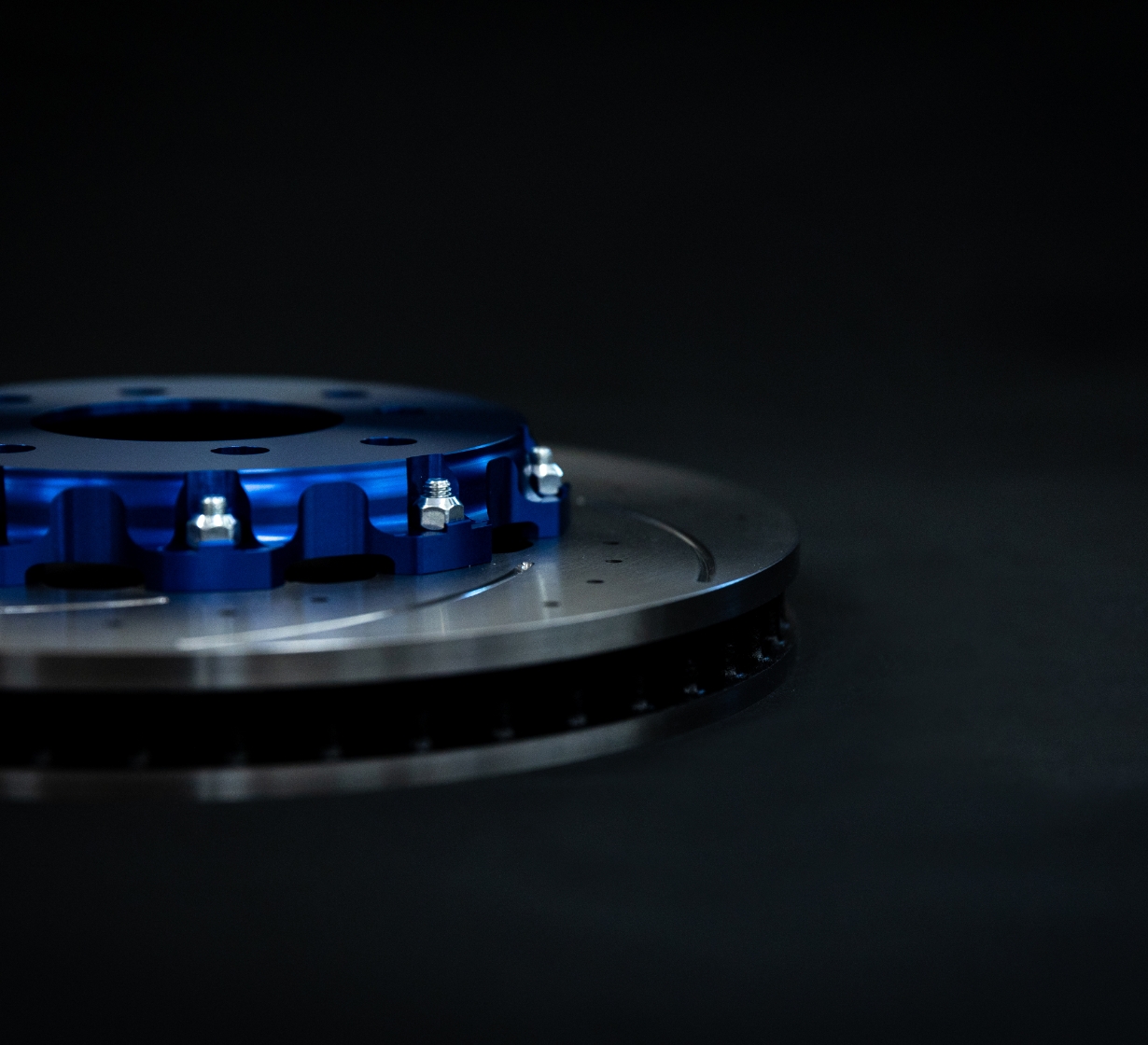

Integrated production system

We can construct an integrated production system with heat treatment/almite/plating/grinding/wire cutting/EDM/buff polishing, etc.

Here in the network of Hamamatsu, which is one of the most famous industrial cities in Japan.

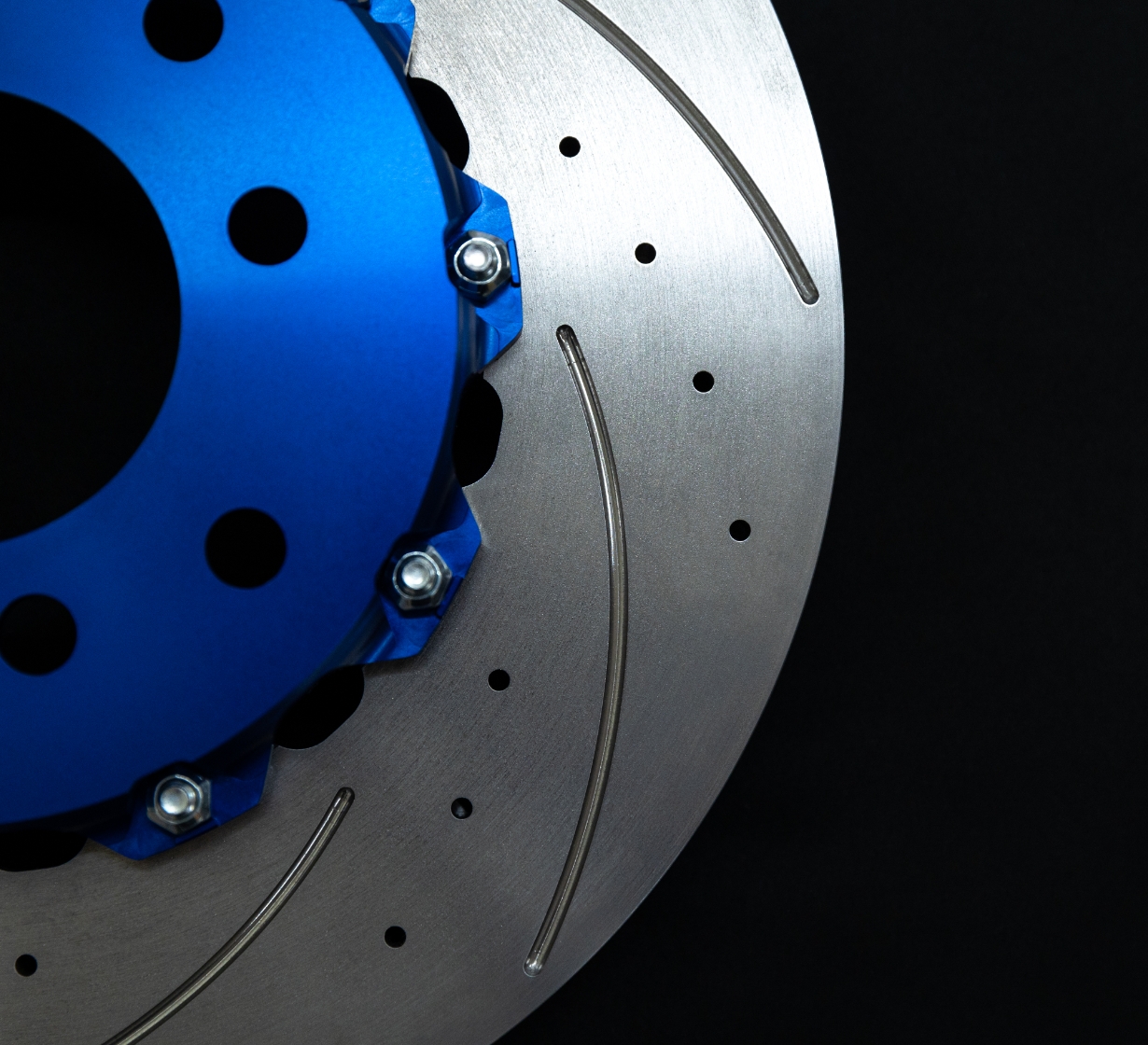

Mass production and prototype

Our higher technology of mass-production has been improved by our challenge for development and prototype of new products.

We learn consciousness of cost by prototype and mass-production.

Mass-production: from 100 to 100,000 pcs/month

Prototype: from 1 to about 20 pcs.

© TSR/Technical Sports Racing